Hello All,

I don't know if this is the right forum to post this kinda questions, so sorry in advance...

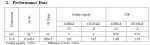

I have a refrigerator with the following performance data table:

Cooling Capacity=> ASHRAE (-23.3)=193W | CECOMAF (-25)=145W

according to test conditions Evaporating Temp. -23.3℃, Ambient Temp. =+32.2℃, Condensing Temp. =+54.4℃, Line-voltage = 220V/50Hz

Sorry i couldn't upload image of table (new member)!!

and I have some questions about compressor since I am new to all of this, I want to control the compressor using a relay on my motherboard, this is the main goal .. I did a little digging but I can't say that I understand all things about compressors!!

1. the compressor starting relay is QPE2-A15MD3!! and it says in compressor datasheet that max current is 8A, so is this contact rating or coil rating? according to what i have seen on some youtube videos, the LRA (current draw at starting) goes through the coil and not contact? and also what's the type of this relay? potential/current relay?

2. the overload protector in compressor datasheet have following characteristics: Max.T.C Amp.(25℃) = 6.0A, Trip time = 5~15 sec, Reset time = 20~180 sec !!

does this mean that if compressor draws more than 6.0A (should LRA be close to this value!!?), overload protector will open circuit?

should I choose my PCB relay's contact limiting value according to this 6.0A ? say a relay of 10A!!?

3. according to this formula "AMPS = (Horsepower x 746) / Voltage" i calculated the horsepower to be = 193W (from datasheet)=HP*746 =>HP=0.25 = 1/4HP.

is my calculation right!?

4. The minimum value of the fuse or circuit breaker shall be no less than 175% of the RLA of the compressor !!? is this a good practice!?

5. I did some calculations to determine the RLA, LRA, FLA:

According to the manufacture’s electrical performance data (see below table):

At -23.3, the FLA (Full Load Amps) (a.k.a. Running Load Amperes) is 193W/220V=0.877A which is the nominal running amps in normal conditions.

And according to "FLA = 0.8 * RLA (Rated Load Amps)" =>

RLA = 0.877/0.8 = 1.1A which is the current where the overload protection will open.

And according to RLA = LRA / 5.56 (for most electric motors LRA is about 5 times greater than its RLA/FLA and some may be 7 times greater.

LRA = RLA * 5.56 = 1.1*5.56 = 6.11A or 1.1*7=7.7A in some cases.

are my calculations right? knowing that i found these formulas here and there from internet!

I would appreciate anyone who could help answer my questions and clear my misunderstanding.

Thank you in advance,

I don't know if this is the right forum to post this kinda questions, so sorry in advance...

I have a refrigerator with the following performance data table:

Cooling Capacity=> ASHRAE (-23.3)=193W | CECOMAF (-25)=145W

according to test conditions Evaporating Temp. -23.3℃, Ambient Temp. =+32.2℃, Condensing Temp. =+54.4℃, Line-voltage = 220V/50Hz

Sorry i couldn't upload image of table (new member)!!

and I have some questions about compressor since I am new to all of this, I want to control the compressor using a relay on my motherboard, this is the main goal .. I did a little digging but I can't say that I understand all things about compressors!!

1. the compressor starting relay is QPE2-A15MD3!! and it says in compressor datasheet that max current is 8A, so is this contact rating or coil rating? according to what i have seen on some youtube videos, the LRA (current draw at starting) goes through the coil and not contact? and also what's the type of this relay? potential/current relay?

2. the overload protector in compressor datasheet have following characteristics: Max.T.C Amp.(25℃) = 6.0A, Trip time = 5~15 sec, Reset time = 20~180 sec !!

does this mean that if compressor draws more than 6.0A (should LRA be close to this value!!?), overload protector will open circuit?

should I choose my PCB relay's contact limiting value according to this 6.0A ? say a relay of 10A!!?

3. according to this formula "AMPS = (Horsepower x 746) / Voltage" i calculated the horsepower to be = 193W (from datasheet)=HP*746 =>HP=0.25 = 1/4HP.

is my calculation right!?

4. The minimum value of the fuse or circuit breaker shall be no less than 175% of the RLA of the compressor !!? is this a good practice!?

5. I did some calculations to determine the RLA, LRA, FLA:

According to the manufacture’s electrical performance data (see below table):

At -23.3, the FLA (Full Load Amps) (a.k.a. Running Load Amperes) is 193W/220V=0.877A which is the nominal running amps in normal conditions.

And according to "FLA = 0.8 * RLA (Rated Load Amps)" =>

RLA = 0.877/0.8 = 1.1A which is the current where the overload protection will open.

And according to RLA = LRA / 5.56 (for most electric motors LRA is about 5 times greater than its RLA/FLA and some may be 7 times greater.

LRA = RLA * 5.56 = 1.1*5.56 = 6.11A or 1.1*7=7.7A in some cases.

are my calculations right? knowing that i found these formulas here and there from internet!

I would appreciate anyone who could help answer my questions and clear my misunderstanding.

Thank you in advance,