I have a Mcquay screw chiller with two circuts. Two circut screws with outside evap and air cooled condensor.

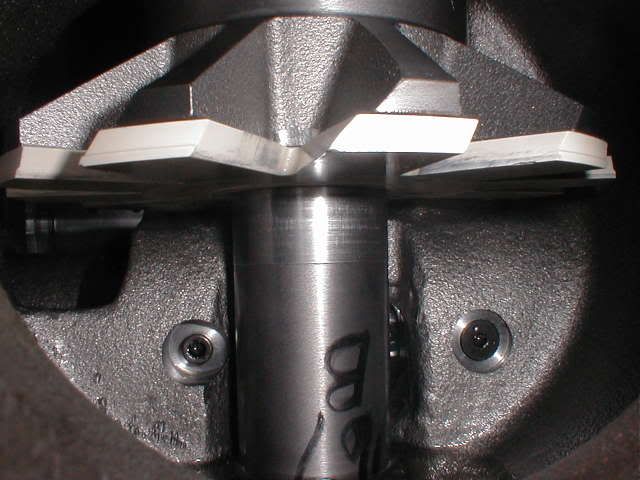

One compressor is making a loud jet engine sound with the suction and discharge the same pressure. The FLA is 160 and the amps drawn are only 50. Any suggestions? Could the shaft to the rotors snap? Is it a solid shaft on the rotors are there keyways? Not familiar with Mcquay. If it is the shaft failure what could have caused it. We just recently took over the Pm. One other note, the chiller does not control the evap pumps and over the winter the evap froze outside (no glycol and heat tape failed). We drained it and took oil and refrig samples and we couldnt find any tube bundle damage. We did not eddy current it but the frozen evap make the compressor shaft fail? It has been running for four or five months with no problems till last week.

Also the liquid line goes back into the compressor and out again to the TXV on the evap. Is this McQuay's way of sub-cooling the liquid?

Signed, Non Mcquay Tech.......lol

One compressor is making a loud jet engine sound with the suction and discharge the same pressure. The FLA is 160 and the amps drawn are only 50. Any suggestions? Could the shaft to the rotors snap? Is it a solid shaft on the rotors are there keyways? Not familiar with Mcquay. If it is the shaft failure what could have caused it. We just recently took over the Pm. One other note, the chiller does not control the evap pumps and over the winter the evap froze outside (no glycol and heat tape failed). We drained it and took oil and refrig samples and we couldnt find any tube bundle damage. We did not eddy current it but the frozen evap make the compressor shaft fail? It has been running for four or five months with no problems till last week.

Also the liquid line goes back into the compressor and out again to the TXV on the evap. Is this McQuay's way of sub-cooling the liquid?

Signed, Non Mcquay Tech.......lol