New to the forum and am a electric utility employee.

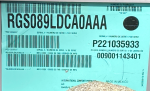

This building has six 7.5 Ton Gas Heating/Electric Cooling Single Package Units. Three are 2007 and three are nine months old. All was well until the electric breaker panel serving these units was changed out. After power was restored, some of the units were found turning wrong rotation . Then three of the compressors failed. Two new, one old.

We can't guarantee how long they ran in this state but long enough for the owner to know something was wrong.

Can this kill a scroll compressor?

HVAC and electrical contractors accepted no responsibility. Their response is "the voltage is too high". The power supply is 480/277 averaging 490VAC phase to phase.

The utility set voltage recorders and found no issues.

This building has six 7.5 Ton Gas Heating/Electric Cooling Single Package Units. Three are 2007 and three are nine months old. All was well until the electric breaker panel serving these units was changed out. After power was restored, some of the units were found turning wrong rotation . Then three of the compressors failed. Two new, one old.

We can't guarantee how long they ran in this state but long enough for the owner to know something was wrong.

Can this kill a scroll compressor?

HVAC and electrical contractors accepted no responsibility. Their response is "the voltage is too high". The power supply is 480/277 averaging 490VAC phase to phase.

The utility set voltage recorders and found no issues.